TBWA\HAKUHODO’s ‘Shellmet’ is an eco-friendly product design solution to marine waste

TBWA\HAKUHODO Tokyo and its partner Koushi Chemical Industry Co. have launched an environment friendly helmet made from wasted scallop shells, in Sarufutsu Village, Hokkaido.

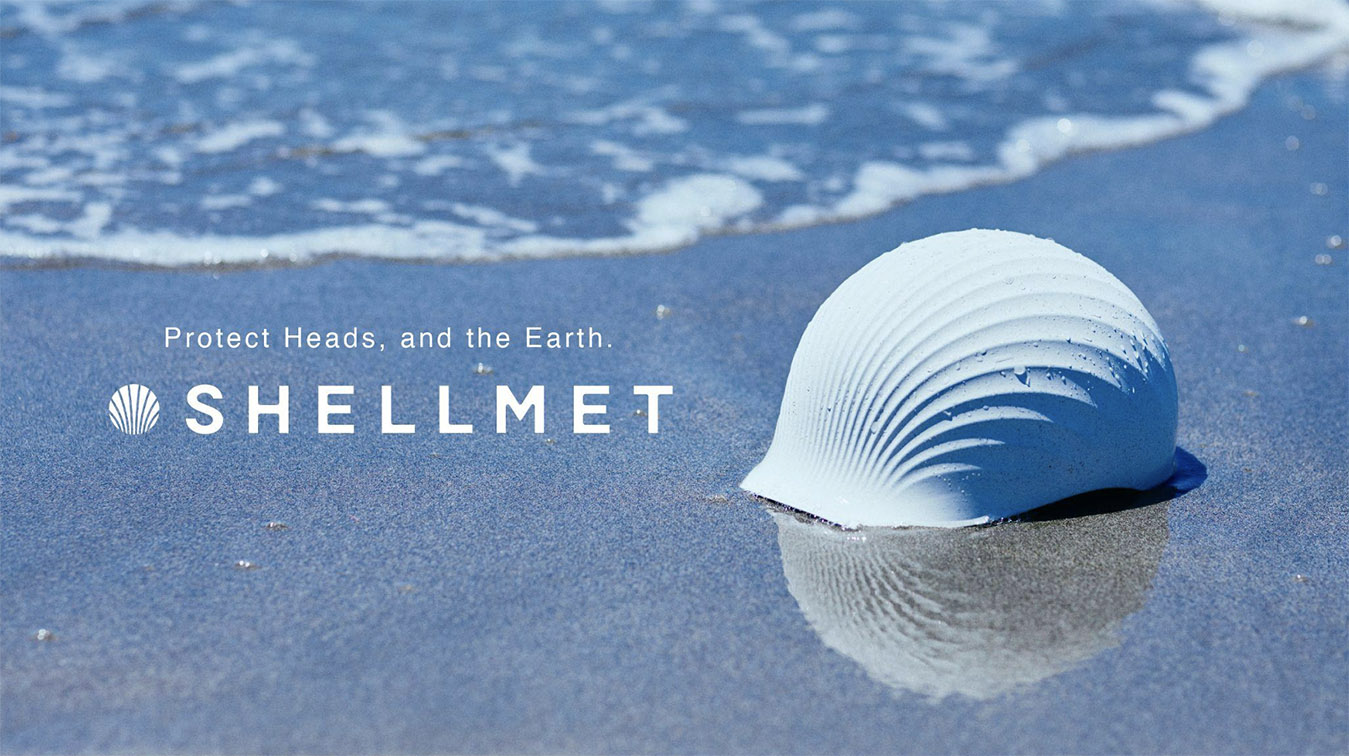

Shells have protected themselves from external enemies, are now protecting people and the planet.

In 2021 the export of scallop shells ceased causing concern for Soya district, where Sarufutsu Village is located, due to the area generating approximately 40,000 tons of shells as marine waste annually. The environmental impact storing the scallops on the ground is hazardous and can lead to serious soil contamination, creating a social issue for the local community.

To help solve the issue of surplus scallop shells, TBWA\HAKUHODO’s discovery that scallop shells main component is calcium carbonate and could be reused as a raw material for a completely new material. The TBWA\HAKUHODO team began efforts to recycle the material, which would become an important resource to support the village

Fisheries Promotion Division, Fisheries Bureau, Hokkaido Department of Fisheries and Forestry, “Survey of Fisheries Waste Generation in FY2021”.

Scallop shells piled up in Sarufutsu Village (photo taken in August 2022)

In nature, the shell’s purpose is to protect itself from outside enemies, and while scallop fishing is dangerous, the idea for “SHELLMET” – a helmet made from scallops to protect scallop fishermen – was born.

The opportunity to scale the product, ‘Shellmet’ to become more than a protective wear for the fisherman became obvious. With the area of Hokkaido hit by major earthquakes, and the risk of disasters such as heavy rain and snow damage due to abnormal weather increasing. From this discovery, the team decided to commercialize the product for use by villagers as disaster prevention helmets to protect themselves.

SHELLMET is made from a new material based on scallop shells whose main component is calcium carbonate, and recycled plastic. It was developed by Koshi Chemical Industry Co. with Professor Hiroshi Uyama of Osaka University with support from Sarufutsu Village in providing surplus shells.

TBWA\HAKUHODO developed the name of “Shellstic (Combination of words “Shell” and “plastic”)” and logo for the new recycled material which is a combination of wasted scallop shells and waste plastic.

Characteristics of “Shellstic”

– Contributes to a maximum 36% reduction in CO2 emissions compared to the use of 100% new plastic

– Contributes to a 20% reduction in CO2 emissions compared to limestone-derived eco-plastics.

– By mixing scallop shells into the plastic, strength (bending modulus) is improved by about 33%.

Furthermore, because Shellstic is an upcycled material, which utilizes waste, the amount of waste will be reduced to not only help solve waste at a local level, but also globally.

SHELLMET is developed based on the concept of “Biomimicry”, which is the application of the mechanisms of the natural world to technological development. SHELLMET incorporates a special ribbed structure in its design that mimics the structure of scallop shells, which is part of the material used for helmet production. As a result, the durability of SHELLMET is improved by about 30% compared to the case without the ribbed structure, even though less material is used.

From material development to product design, creating a product with minimal burden on the environment and sustainability have been central to this process. SHELLMET upcycles scallop shells that would have otherwise been discarded.

The product is available in a total of five color variations: CORAL WHITE, SAND CREAM, DEEP BLACK, OCEAN BLUE, and SUNSET PINK all colors inspired by the oceans, and can be used for a variety of purposes, including disaster prevention, work, and commuting by bicycle.

In Sarufutsu Village, approximately 270 fishermen wear plastic helmets daily, we will promote the use of eco-plastic by using helmets made of shell-derived eco-plastic as a trial starting in the spring of 2023.

In addition, we plan to gradually develop “SHELLMET” by stockpiling it as a disaster prevention product, selling it to the general public, and introducing it as a tax return gift for hometowns * (* Furusato Nozei: Japan’s tax reduction system for the taxpayers who donate to local municipalities). Through this initiative, they aim to promote the active use of reusable materials and raise awareness of disaster prevention among village residents.

TBWA\HAKUHODO, Creative Director, Masatoshi Usami, said: “Scallops are the most commonly eaten shellfish by Japanese people – and it is also the shellfish that results in the most amount of waste. If scallop shells are viewed as a resource, rather than waste, they offer new possibilities as a sustainable material. SHELLMET is the first of these. Shells that have protected itself from external enemies can now be used to protect human lives. We hope this project will spread throughout society as a new form of environmental conservation that solves the problem of ocean discards and protects the fishing industry.”

Product Designer, Shintaro Monden (quantum), said: “SHELLMET’s shell-like structure is based on the idea of biomimicry and designed to be both visually pleasing and functionally thoughtful. From material development to design, we aimed to create a sustainable product with minimal burden on the environment. With its minimalistic design, the lightweight and robust SHELLMET can be used for a long period of time in various situations, from daily use to work sites. Not only the helmet itself, but also other parts including the buckle are all original designs, which give the wearer the feeling that every detail has been carefully crafted, giving the pleasure to own SHELLMET.”

Koushi Chemical Industry Co., Planning & Development Supervisor, Tetsuya Nambara, said: “Various new eco-plastics are currently being released under the theme of SDGs. However, the reality is that true eco-plastics that meet cost, quality, and sustainability requirements are very limited at this time. While new materials are being mass-produced, hundreds of thousands of tons of waste are incinerated or landfilled each year that could still be used. We believe that it is essential to recycle more waste than ever before in order to promote a sustainable society.

“We are pleased to be able to collaborate with the people of Sarufutsu Village and help solve social issues in the region. We are committed to building a sustainable society that utilizes waste, and we hope that similar efforts will spread throughout Japan and around the world.”

Sarufutsu Village Mayor, Koichi Ito, said: “The effective use of “scallop” shells, the treasure of Sarufutsu Village, has been sought for many years. We believe that we can contribute to the realization of a sustainable society if scallop shells, which have once finished their role of protecting itself from external enemies, can next be reborn and become a helmet to protect people’s heads. First, we plan to use them for fishermen and as disaster prevention equipment. Sarufutsu Village will continue to seek ways to realize a sustainable society, not limited to the use of Sarufutsu scallops.”

Credits

Agency TBWA\HAKUHODO

Chief Creative Director Takahiro Hosoda

Creative Director Masatoshi Usami

Senior Art Director Yuhei Ito

Art Director Takeshi Matsuda

PR Planner Kyosuke Hashimoto

PR Planner Suguru Kato

Producer Yuki Sakamoto

Producer Omu Inoue

Project members

Product Designer Shintaro Monden (quantum)

CAD Modeling Minatsu Takekoshi (quantum)

Director Kohei Inoue (Robot Communications)

Photographer Junya Taguchi (Freelance)

Designer Hisahiro Tomonaga (spice)

Retoucher Takumu Koshiba (CONTRAST Inc)

PR Promoter Eri Sato (KMC)

PR Promoter Takayuki Tamada (KMC)